© Jean-Paul Bertemes (FNR) & Moast Creative Studios

In this episode of "My research in 90 seconds", Vincent Jalaber explains how new materials can be produced using cold plasma technology!

Explaining its research in less than 90 seconds: 8 young researchers from Luxembourg took up the challenge in the 2nd edition of the video series "My research in 90 seconds". In this episode, Vincent Jalaber explains how new materials can be produced using cold plasma technology! More about this in the video - and further details in his article.

The video and the accompanying article were produced as part of a “Science Communication Course” for PhD students at the University of Luxembourg.

Author Text: Vincent Jalaber (PhD at LIST)

Editor: Michelle Schaltz (FNR)

Video: Jean-Paul Bertemes (FNR) & Moast Creative Studios

After scientists studied the remarkable adhesion properties of mussels to various types of surfaces under harsh marine conditions, they established a link between these remarkable adhesion properties and high concentrations of a chemical group named catechol, produced by the mussels. Since the discovery, synthetic catechol coatings have been used in the production of advanced materials for biomedical applications or energy production. The production of these synthetic catechol coatings traditionally relies on chemical techniques, which produce a lot of chemical waste. As an alternative to these chemical methods, scientist now have turned to cold plasma processes. They offer unique advantages such as easy integration into industrial production lines and fast processing.

What is plasma?

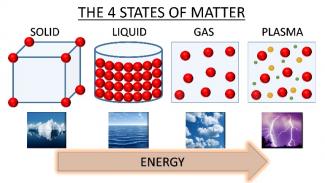

Plasma is considered as the 4th state of matter (the three other states being solid, liquid and gas) and makes up for 99.9% of our universe. In nature, the plasma state can be found in lightning, northern lights, flames or the sun. Artificial plasmas are used in neon tubes, for welding or in the flash of a torch. It is possible to generate a plasma by supplying energy to a gas. The energy can be applied thermally, by electromagnetic radiation or by an electric current.

We distinguish between hot and cold plasma

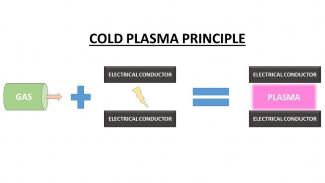

Plasma can be classified according to its density, temperature and degree of ionization. A cold plasma is obtained using a cold gas (from room temperature to a few hundred degrees). It is very weakly ionized and therefore consists essentially of atoms and neutral molecules. In contrast, a hot plasma is totally ionized, consisting only of ions and electrons with temperatures reaching tens of millions of degrees.

How does a cold plasma coating procedure work?

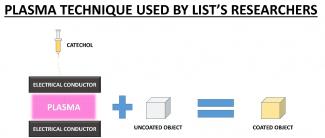

LIST’s scientists have developed coatings using a cold plasma process. To generate the plasma, the scientist insert a neutral gas into a generator and apply a voltage, in order to ionize the neutral gas, trapped between two electrical conductors.

How is cold plasma used in the coating process?

At first, the researchers place the material to be coated between the two electrical conductors. Then they generate the plasma and send the catechol with a syringe directly into the plasma. It only takes a few minutes for the material to be covered by catechol compounds. The catechol compounds confer the coated material strong adhesive properties and transform it into an advanced material, which has promising applications in the biomedical industry.